3D LASER SCANNING

At Inisys we have over 17 years of experience in the digitization and surveying of complex process plants and factories, providing the latest 3D laser scanning services in South Africa

- Eliminate errors and project costs

- Improve project coordination

- Ensure equipment fits the first time

- Visualise complex facilities

Simply fill in this form and we will contact you or call us now >

SET UP A FREE CONSULTATION

3D LASER SCANNING

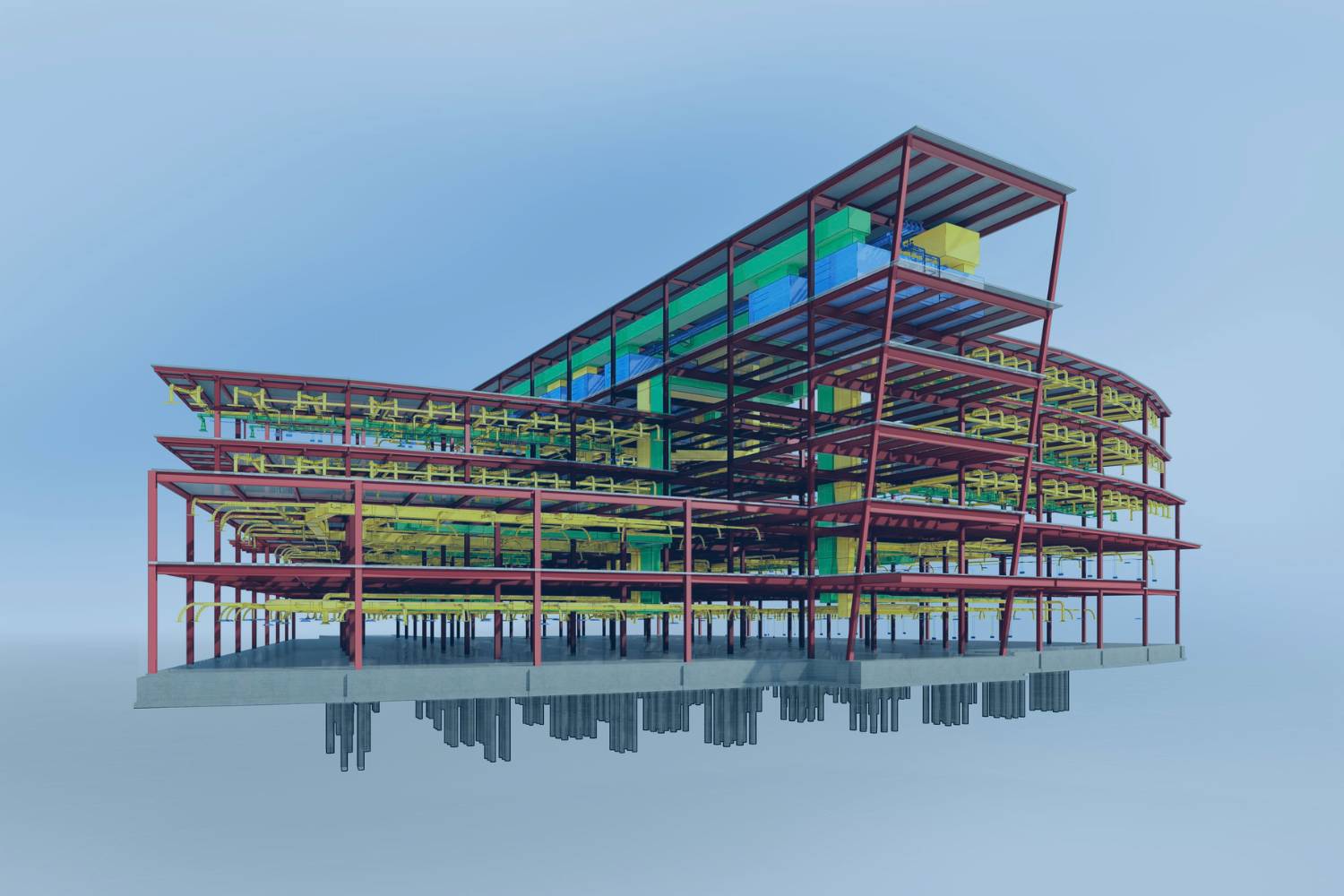

3D laser scanning is the fastest and most cost-effective method to capture the as-built conditions of any plant

Inisys Africa BIM Solutions has been involved in 3D laser scanning since 2004 when we bought our first 3D Laser scanner.

We specialise in the process plant environment where accuracy is critical when capturing as-built information for a project. As plants evolve over the years, there are numerous changes to plant assets that are not necessarily reflected in the existing document management system.

When it comes to piping and changes to these process plant, the ability to prefabricate piping off-site with mm accuracy, plan the rigging and installation can save the plant millions in downtime alone.

3D laser scanning can be used to capture piping, structures, equipment, civil and electrical layouts

LASER SCANNING

3D LASER SCANNING PROCESS

3D Scan & Registration

Using the Leica ScanStation P series which delivers the highest quality 3D data and High-Dynamic Range (HDR), we conduct a 3D scan of the interior and exterior of your building

Data Processing

Data is processed on a cloud-based system where it is organised and analysed by our team of experienced engineers.

Visualisation & Application

Data is converted into an optimised model for use downstream such as a BIM Model or Plant Model for application on refurbishments & upgrades, space planning, asset mapping & management etc

WHY

WHY USE 3D LASER SCANNING?

OUTDATED PLANT DOCUMENTATION

As plants evolve over the years and requiring new and innovative ways to optimise their processes, there are numerous changes to plant assets which are not necessary reflected in the existing document management system

COSTLY SHUT DOWN PREPARATIONS

Many businesses do not have accurate and complete as-built models of their plants. This gap between what is in the plant and what is on existing drawings in the office generates time-consuming exercises and resources for shutdown preparations or any changes to a brownfield plant

RAPID MEASUREMENT

The rapid speed of data capture from 3D laser scanning allows millions of data points to be recorded in seconds. This ensures that large environments can be surveyed in a short timescale and makes 3D surveying ideal for work on any time-sensitive projects

REDUCED RISK IN DATA CAPTURING

The 3D scanner is ideal for hazardous or hard-to-reach areas. 3D scanners allow surveyors to capture environments without the need to physically access the area

COST & TIME SAVINGS

Due to the rapid nature of data capture and reduced HSE risk we require fewer man-hours on site, minimal disruption and downtime of facilities, environments and the reduction of HSE preventative measures we can save clients time and money on their plant modeling requirements

SOLUTIONS

SCANNING SOLUTIONS

CHOOSE US

WHY CHOOSE US?

ESTABLISHED FOR OVER 17 YEARS

Operating since 1999 we have years of experience. Inisys Africa BIM Solutions has been involved in 3D Laser scanning since 2004

USING THE BEST QUALITY TECH

Inisys uses the Leica ScanStation P series which delivers the highest quality 3D data and High-Dynamic Range (HDR) imaging at an extremely fast scan rate of 1 million points per second at ranges of up to 120m. Unsurpassed range and angular accuracy paired with low range noise and survey-grade dual-axis compensation form the foundation for highly detailed 3D colour point clouds mapped in realistic clarity

WE HIRE ONLY THE BEST

Equipment is only as good as its operator. We have a team of skilled draftsmen and engineers who work on every project. Some of our board members were the first innovators in South Africa to offer 3D Laser Scanning to businesses

COUNTRY AND GLOBAL OFFICES

We offer our 3D Laser Scanning service all over South Africa and have worked with clients in Johannesburg, Pretoria, the Western Cape and KwaZulu-Natal. We also have a dedicated office in Dubai

BOOK A CONSULTATION

3D laser scanning is the fastest and most cost-effective method to capture the as-built conditions of any plant, whether it is the piping, structures, equipment layout, civil or Electrical.

3D LASER SCANNING APPLICATIONS

There are many reasons why you might want to utilise 3D laser scanning on a project. At Inisys most projects we work on are refurbishments, retrofits, or upgrades to existing facilities. Factories and manufacturing plants are complex ever-changing environments and often have old or outdated 2D plans.

If you are installing news lines or machinery and something doesn’t fit, it can cost thousands of rands in rework and delay production. By having an area 3D laser scanned any issues can be easily identified and designed out at this stage ensuring a smooth first-time fit.

FAQ

FREQUENTLY ASKED

What is 3D Laser scanning?

3D laser scanning uses lasers to measure an object’s geometry to craft a digital 3D model. This technology is used throughout a number of industries and settings, at Inisys we specialise in the process plant environment where accuracy is crucial

What is the 3D Laser Scanning process?

In its most basic form, we see 3D Laser scanning as a three-stage process. First the actual scanning process using specialist scanning equipment, secondly the processing of this information and third, the output of this data into the desired solution

How accurate is 3D Laser scanning?

Inisys uses the Leica ScanStation P series which delivers the highest quality 3D data and High-Dynamic Range (HDR) imaging at an extremely fast scan rate of 1 million points per second at ranges of up to 120m. The unit which Leica Geosystems describes the angular accuracy of the P series and C series instruments is arc seconds, a unit so small it is perhaps difficult to grasp

How much does 3D laser scanning cost?

Answer

TESTIMONIALS

WHAT OUR CUSTOMERS SAY

Over the past year have utilised the Inisys Africa BIM Team, for 3D Laser Scanning and modelling technologies on a number of projects which has saved us a considerable amount of time and resources

Dimitri Simigiannis

LSL Consulting

We have done a couple of projects where 3D scanning of the existing plant is used. The result for the completed project was a “perfect fit” Tie-in between the New and Existing civils, structures and pipe racks. The 3D scan enables us to use minimal site engineering hours or rework to achieve this

Barry Beylefeld

Azmet

STILL UNSURE?

We are here to help. Get in touch with us and we can run through our Engineering solutions with you

BIM SOLUTIONS

We provide cutting edge and economical BIM (Building Information Modelling) Design Solutions that will augment the profitability of your business. Find out more about our BIM Solutions and how it can save you time and money

DIGITAL TRANSFORMATION

Covering the full lifecycle from projects to operations, the Datum360 Connected Data Platform will intelligently manage and connect all your Engineering Information, models and documents

OUTSOURCED DRAWING OFFICE

Set up a partnership with us where you can outsource some or all of your drawing office. Gain access to a highly flexible resource that integrates with your business and puts you in control

CONSULTATION SERVICES

Inisys can provide you with consulting services and act as an extension to your team by providing expert support and advice. Our team of qualified engineers can provide invaluable advice